ZEVAC – WE MAKE YOUR PRODUCTS WORK

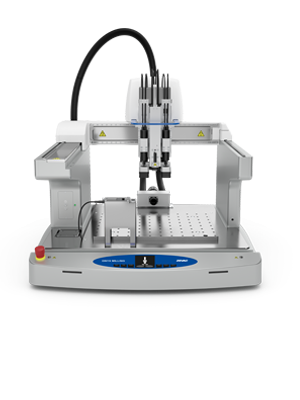

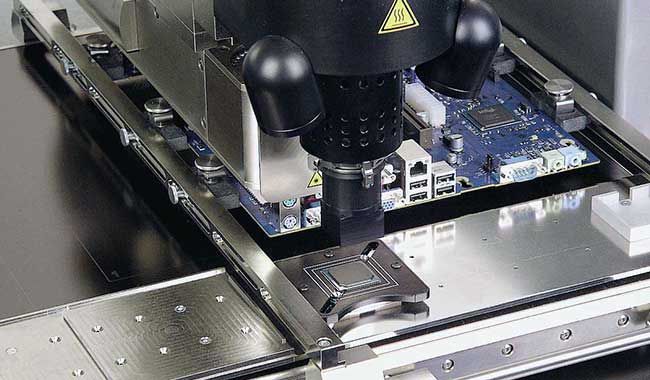

ZEVAC develops and manufactures machines for component placement and assembly, including soldering processes, with a focus on printed circuit board repair systems within the electronics manufacturing process.

Development: 100% in Switzerland – Production: 95% in Switzerland

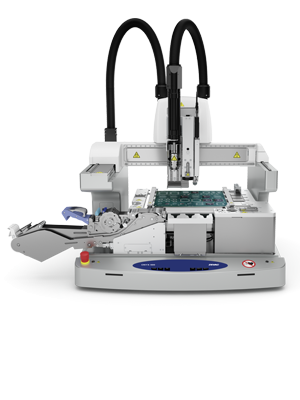

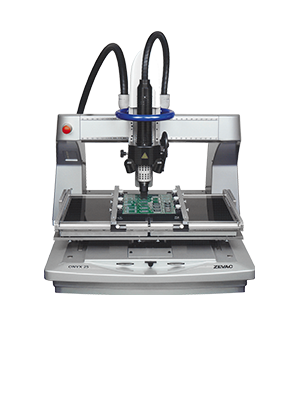

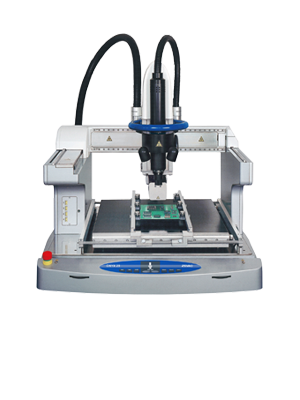

THE NEW ONYX 49 & 1000

The new ONYX 49 and ONYX 1000 are designed to rework large SMD boards up to 800 mm x 630mm.

The ONYX 49’s robust design and fully automatic axes ensure maximum process accuracy and repeatability.

Further information: ONYX 49

The ONYX 1000 is the only truly fully automated rework solution on a large platform, allowing the entire process to be completed autonomously at the click of a mouse.

Further information: ONYX 1000